A die cut is a fabulous creation that adds a touch of magic to any print project. It’s like the fairy godmother of the printing world, turning your design dreams into reality. But what exactly is a die cut and how does die cutting work?

Discover the fascinating world of die cutting and learn how this intricate process works.

What does die cut mean?

Imagine you have a piece of paper and a design that you want to cut out of it. Die cutting is the process of using a die, which is like a cookie cutter for paper, to cut precise shapes and patterns in various materials. The die is a custom-made tool that consists of a sharp blade crafted into the desired shape. It’s mounted on a sturdy base, ready to work its magic.

Die cutting machines are the wizards that bring the die to life. These powerful machines apply pressure to the die, pressing it into the material and slicing through it effortlessly.

One fascinating aspect of die cutting is its versatility. Not limited to just paper, die cutting can be used on a wide range of materials such as cardboard, fabric, foam, and even thin plastic sheets. This opens up a world of creative possibilities for designers and marketing specialists.

Types of Die Cutting Machines

Just like there are different types of wands for different spells, there are also different types of die cutting machines. The most common types include manual, semi-automatic, and fully automatic machines. Manual machines require human intervention, making them perfect for small-scale projects or for those who love a hands-on approach. Semi-automatic machines strike a balance between manual and automatic, offering a bit of both worlds.

Fully automatic machines, on the other hand, are like the crystal ball of die cutting. They can handle large volumes of cutting with minimal human intervention. These machines are the go-to choice for production houses and online printing companies like us, Printulu, where efficiency and speed are essential.

It’s worth noting that within these categories, there are further distinctions based on the cutting mechanism. For example, some die cutting machines use flatbed cutting, where the material is placed on a flat surface for cutting. This method is commonly used for materials like paper, card stock, and fabric. On the other hand, rotary die cutting machines use a cylindrical die to cut materials in a continuous roll form, making them ideal for high-volume projects.

Additionally, advancements in technology have led to the development of laser die cutting machines. These machines use a high-powered laser to cut through materials with precision and speed. While they may come at a higher cost, their ability to cut intricate designs with ease makes them a popular choice in industries like packaging and signage.

How to Set Up Artwork for a Die Cut

Setting up your artwork for the die is fairly easy:

- Create an outline where the artwork needs to cut on a separate layer.

- Set the outline to 0,35mm

- Create a spot colour with the values: C:0, M:100, Y:0, K:0

- Name the Spot colour Die line

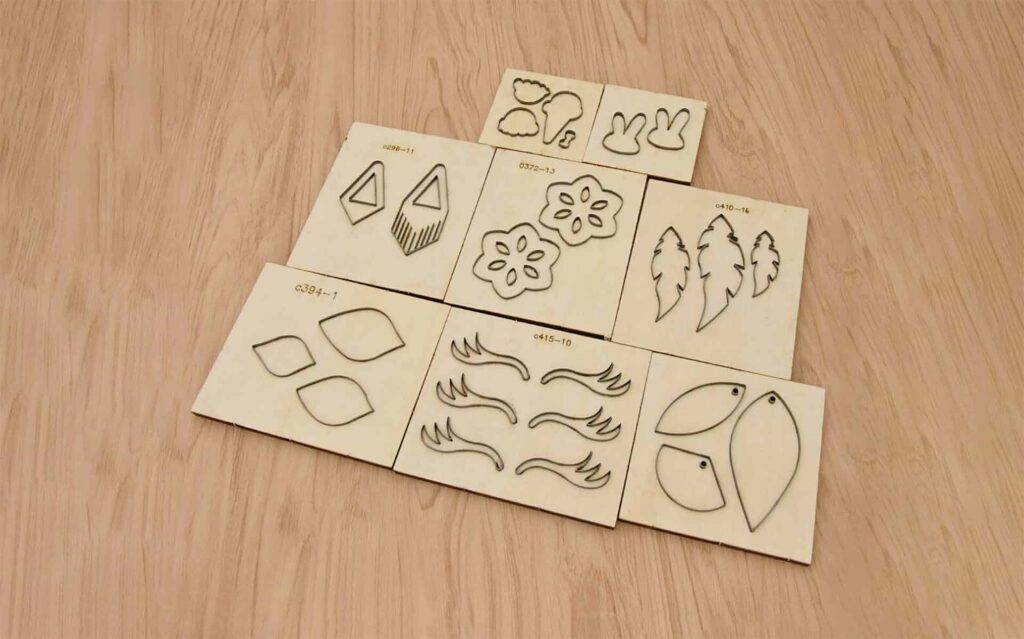

Here is an example, similar process but for stickers:

Common Applications of Die Cutting

Die cutting is a versatile. From greeting cards and invitations to packaging and labels, die cutting adds that extra touch of pizzazz that makes your prints stand out. It’s the secret ingredient that turns ordinary prints into extraordinary works of art.

In the world of online printing, companies like Printulu harness the power of die cutting to offer unique and custom-made creations for their customers. Whether it’s a die cut business card, a die cut folder, or a die cut flyer, the possibilities are endless.

Die cutting is not only limited to paper products; it is also widely used in the production of fabric and leather goods. Fashion designers often utilise die cutting to create intricate patterns and designs on garments, bags, and accessories. The precision and efficiency of die cutting machines ensure that each piece is cut with accuracy, resulting in flawless finished products.

Moreover, the automotive industry benefits greatly from die cutting technology. Car manufacturers use die cutting to produce gaskets, seals, and interior components with precision and consistency. This process not only streamlines production but also ensures that the final products meet the high standards of quality and durability required in the automotive sector.

Advantages and Limitations of a Die Cut

When it comes to advantages, die cutting has a whole handful to offer. It allows for intricate designs, precise cuts, and limitless creativity. It adds a luxurious touch to any print project and can give your business a professional edge. Plus, with the right die cutting machine, the process can be fast and efficient, just like waving a wand.

But like any magic, die cutting also has its limitations. It may not be the best choice for extremely large-scale projects, as the size of the die may become a constraint. Additionally, the cost can be higher compared to traditional cutting methods, especially for small quantities.

So there you have it, the enchanting world of die cutting. It’s a mesmerising process that transforms your prints into something extraordinary. Next time you see a beautifully crafted design with intricate shapes, you’ll know that it’s the result of the art of die cutting. So go ahead, embrace the magic, and let die cutting work its spell on your printing projects.

Follow the basic guidelines in our print-ready artwork checklist and you’ll be all set. If you ever have any concerns or are uncertain about anything, give us a call at 010 593 0558 or drop us a quick email at [email protected].

If all else fails, we’ve got fantastic professional design services that can take care of the whole process for you. We’re always happy to help!